- +86 17772158833

- Email:Market@jiulongglass.com

- Mon to Sat: 08:30 am to 06:30 pm

- Home

- Products

- About Us

- News & Blogs

- Contact Us

- Download

- System Door and Window

- Home

- Products

- About Us

- News & Blogs

- Contact Us

- Download

- System Door and Window

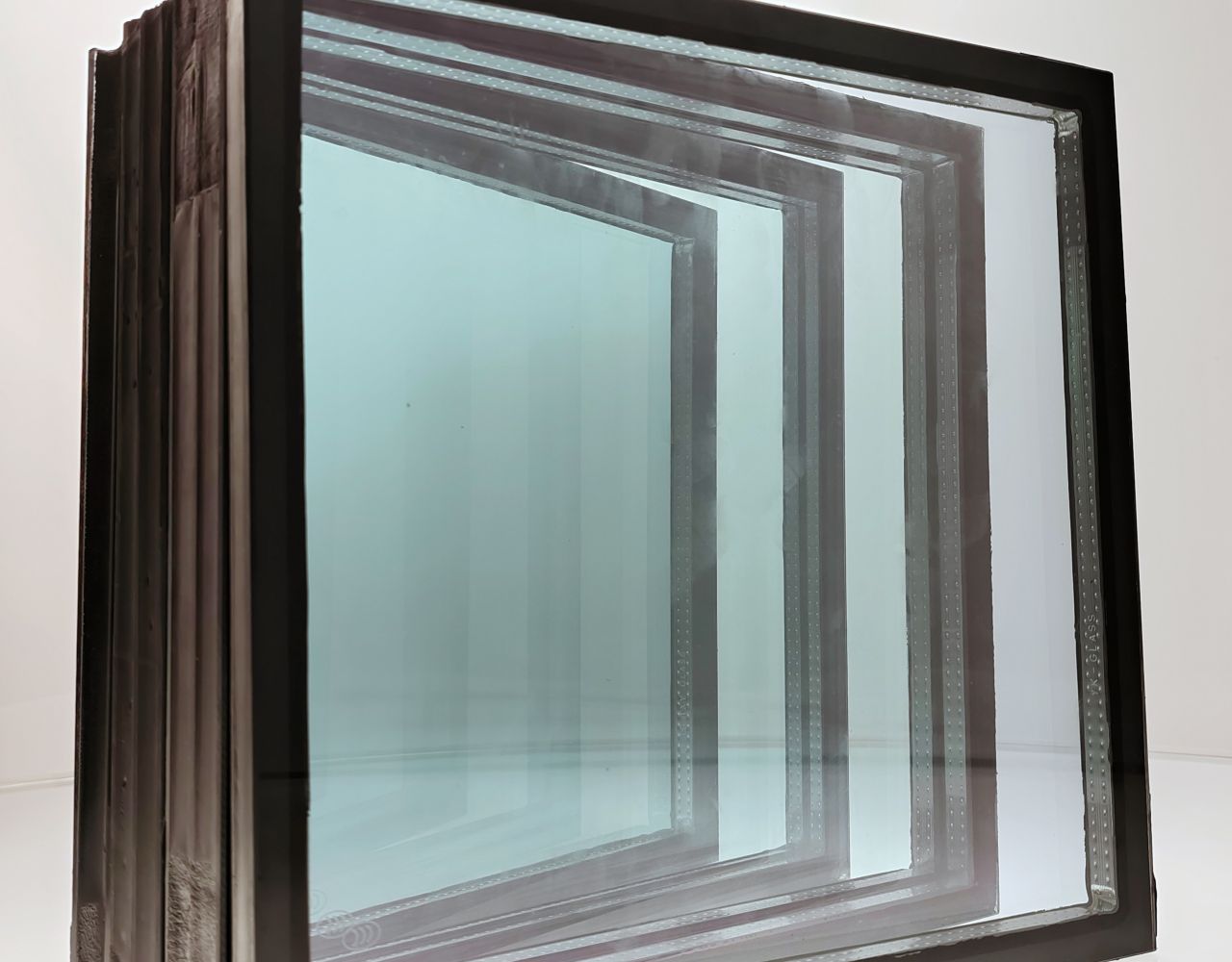

Insulated Glass

Insulated glass is a glass product in which two or more pieces of glass are evenly separated by effective support, and the periphery is bonded and sealed to form a dry gas space between the glass layers.

Insulated Glass Product Technical Specification

Thickness: 4+9A+4mm, 5+9A+5mm, 6+12A+6mm, 6+16A+6mm, 8+16A+8 or Customized

Size: Min size: 300*200mm, Max size: 2140*3300mm Customized Size

Color: Clear, Ultra Clear, Bronze,Blue, Green, Gray, Black, Frosted, Etc.

Insulating Gas: Air or Argon

Advantage

1.Good heat insulation performance. One is the relatively static gas in the hollow layer, which effectively isolates convective heat transfer. Secondly, there is a layer of metal film on the surface of the Low-e glass, through heat reflection,the effect of preventing the outdoor heat from entering the room in summer and the indoor heat from being lost to the outside in winter obvious, and the insulation performance is better.

2.Good sound insulation performance. Insulating glass can reduce the noise by 27- 40 decibels. If composite hollow glass is used, the noise will be reduced even more, and it will have an ideal mute effect even near the airport.

3.Good wind pressure resistance. The wind pressure resistance of insulating glass is 15 times that of a single piece of glass, and the glass is not easy to self-explode.

4.No frost or condensation. The Insulating glass is affected by the middle air insulation layer, and even if the outdoor temperature is very low, it will not cause frost and condensation on the glass surface. The dew point of the insulating glass can reach -60℃ .

01

Make a processing order

After the order is sent to the factory office, print out the original order, input the width, height, quantity, and configuration of the glass into the computer, and calculate the total area. Draw CAD drawings for special shapes and those that need to be cut and drilled. Select the original glass with the highest yield, layout it, and export it to the dongle.

02

Workshop processing

The finished order is sent to the production workshop, and the layout in the dongle is imported into the fully automatic cutting machine. According to the requirements of the processing order, the glass is cut, edged (if it needs to be cut and drilled, it should be done before tempering), tempered, hollowed, and laminated.

03

Quality inspection and packing

After production is completed, the quality inspectors will inspect the quality of the products and count the quantity. After ensuring that there are no quality problems and quantity shortages, the delivery personnel will pack the glass into wooden boxes. The glass is padded with rubber pads and the outside of the wooden box is tied with steel belts.

Related Products

Low-E Insulated Glass

LOW-E insulating glass not only has significant advantages in energy saving and emission reduction, but can also improve the comfort and sustainability of buildings. Therefore, it is widely used in windows and curtain wall systems of modern buildings.

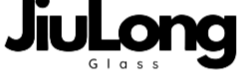

Triple-Layer Insulating Glass

Triple-layer insulating glass is a high-performance architectural glass suitable for buildings with high requirements for heat insulation, sound insulation, safety and energy saving.

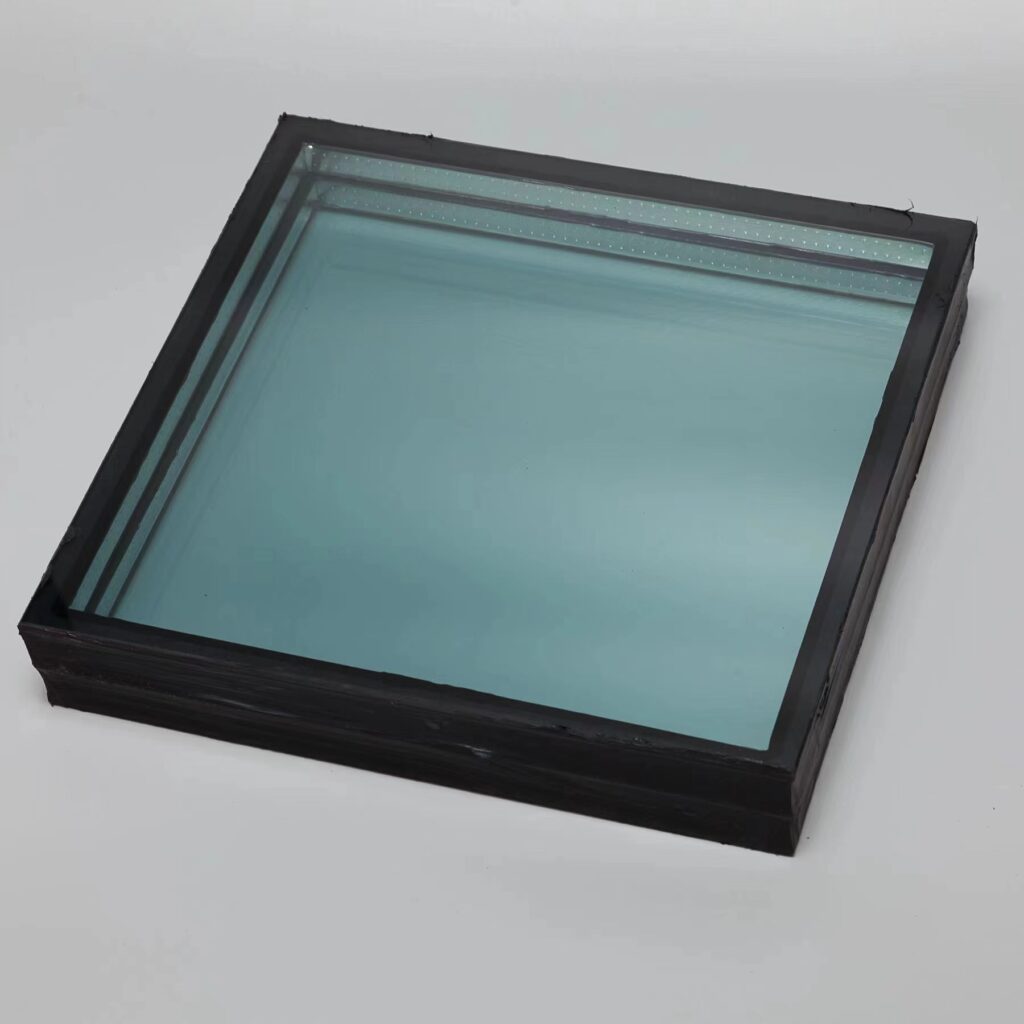

Tinted Insulated Glass

Tinted insulating glass is not only visually appealing, it also provides practical benefits such as privacy protection, solar control, energy conservation and durability.

Jiulong Guarantee

We adhere to the philosophy of "customer first, integrity management" and are committed to creating more value for employees, customers and society. We will continue to strive to improve our technical level and service quality to meet customer needs and expectations.

Customized service

Each project will have professional technicians to provide you with professional services and design drawings if necessary.

Fast and accurate quotation

After the project drawings, dimensions, details and other information are confirmed, we will provide you with an accurate quotation within 3 days.

Quality Control

Our quality control program is a technological approach with consistent monitoring of quality throughout the manufacturing process.

On time packaging and shipment

We package the products within the agreed time and ship them 100% on time.

Production process supervision

During the production process, we will keep in touch with you at all times to let you know the production progress of your order.

After-sales service

After receiving the goods, if there are any installation issues that require assistance, we will provide free online installation guidance services.