- +86 17772158833

- Email:Market@jiulongglass.com

- Mon to Sat: 08:30 am to 06:30 pm

- Home

- Products

- About Us

- News & Blogs

- Contact Us

- Download

- System Door and Window

- Home

- Products

- About Us

- News & Blogs

- Contact Us

- Download

- System Door and Window

Laminated Glass

Laminated glass is composed of two or more pieces of glass, through the PVB film in the middle of the glass, under heat and pressure, the glass and the intermediate film are permanently bonded together.

Laminated Glass Product Technical Specification

Glass Thickness: 3+3mm, 4+4mm, 5+5mm, 6+6mm, 8+8mm, 10+10mm, 12+12mm, 8+8+8mm, 10+10+10mm, customized.

Film Thickness:0.38mm,0.76mm,1.14mm,1.52mm, 1.9mm,etc.

Size: Min size:Customized Size

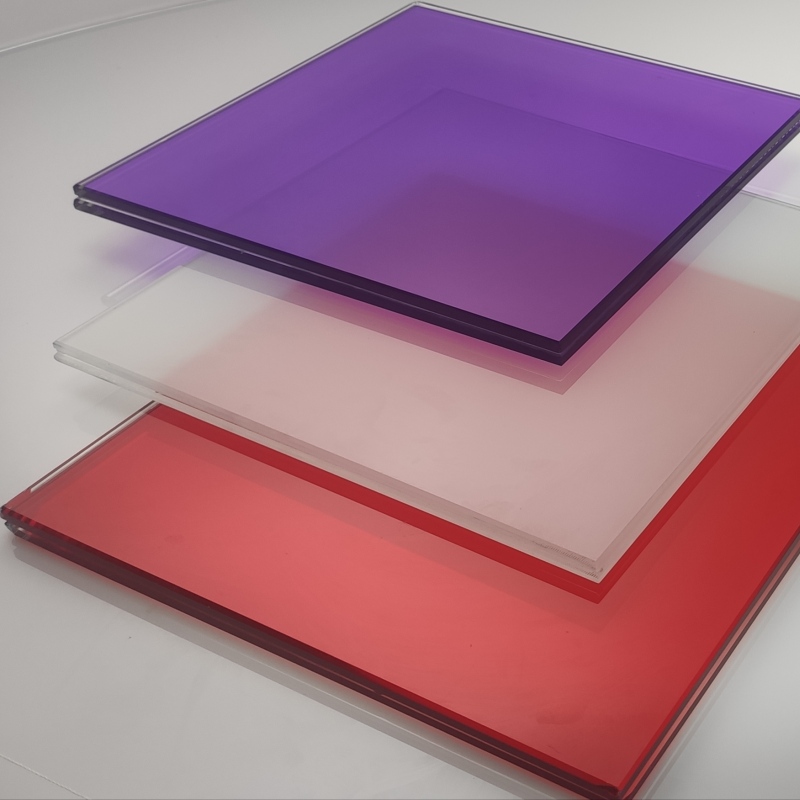

Color: Both Glass and Film color can be Customized

Advantage

1.Security. When the laminated glass is impacted by external forces, due to the strong toughness of the inter layer film, it is difficult to be broken, and has good impact resistance. Even if the glass is broken, the fragments will stick to the film and will not scatter, ensuring personal safety.

2.Sound insulation and heat insulation. The PVB film in the middle can block the transmission of sound waves, reduce noise intrusion, maintain quietness, and maintain a comfortable home environment.

3.UV protection. Laminated glass also has the function of filtering ultraviolet rays, which can effectively protect people's skin from sunburn and can also prevent valuable furniture items from being faded by the sun.

01

Make a processing order

After the order is sent to the factory office, print out the original order, input the width, height, quantity, and configuration of the glass into the computer, and calculate the total area. Draw CAD drawings for special shapes and those that need to be cut and drilled. Select the original glass with the highest yield, layout it, and export it to the dongle.

02

Workshop processing

The finished order is sent to the production workshop, and the layout in the dongle is imported into the fully automatic cutting machine. According to the requirements of the processing order, the glass is cut, edged (if it needs to be cut and drilled, it should be done before tempering), tempered, hollowed, and laminated.

03

Quality inspection and packing

After production is completed, the glass is displayed in the warehouse. The quality inspectors will inspect the quality of the products and count the quantity. After ensuring that there are no quality problems and quantity shortages, the delivery personnel will pack the glass into wooden boxes customized according to the size of the glass. The glass is padded with rubber pads and the outside of the wooden box is tied with steel belts.

Related Products

Ultra-Clear Laminated Glass

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

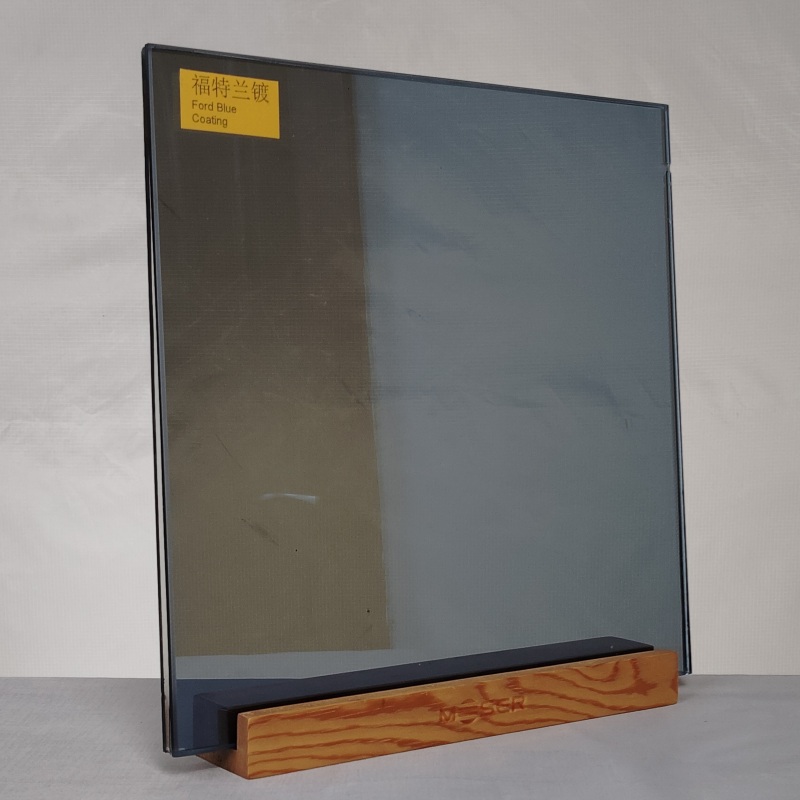

Coated Laminated Glass

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Tinted Laminated Glass

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Jiulong Guarantee

We adhere to the philosophy of "customer first, integrity management" and are committed to creating more value for employees, customers and society. We will continue to strive to improve our technical level and service quality to meet customer needs and expectations.

Customized service

Each project will have professional technicians to provide you with professional services and design drawings if necessary.

Fast and accurate quotation

After the project drawings, dimensions, details and other information are confirmed, we will provide you with an accurate quotation within 3 days.

Quality Control

Our quality control program is a technological approach with consistent monitoring of quality throughout the manufacturing process.

On time packaging and shipment

We package the products within the agreed time and ship them 100% on time.

Production process supervision

During the production process, we will keep in touch with you at all times to let you know the production progress of your order.

After-sales service

After receiving the goods, if there are any installation issues that require assistance, we will provide free online installation guidance services.